WHAT IF PACKAGING WOULD NEVER CAUSE HARM TO THE ENVIRONMENT?

Designed for nature: material that breaks down, not the environment.

Designed for nature: material that breaks down, not the environment.

Our consumption model needs circularity and non-toxic materials. Either humans recycle via an industrial recycling system (technical cycle) or Earth recycles, via its inherent biological capabilities to decompose materials and create something new out of them. The truth is: the global recycling infrastructure is incapable of handling the waste that we produce. Only 9% of plastics get recycled globally, and what is littered often carries toxins and microplastics with it.

This is why we have designed CAMM to work in any cycle, most importantly in the biological cycle and to be fully free of toxins, eternal chemicals and microplastics.

The minimum standard behind is the home compostability. We conduct extensive studies to ensure and prove this quality of our material, e.g. with studies from OWS and more recently a certification by TUV Austria according to the French standard.

What Does Home Compostability Mean?

Home compostability refers to the ability of materials to decompose naturally in a typical home composting environment. Unlike industrial composting, which occurs under controlled, high-temperature conditions, home composting takes place in a much more variable environment, such as a backyard compost bin or pile. This sets high standards for certification: for packaging to be truly home compostable, it needs to break down quickly and safely without leaving harmful residues behind.

And to be precise: we are talking “home” compostability, not “industrial” compostability (it’s nice but not the full answer).

What is the Difference?

While both home and industrial compostability refer to the biodegradation of materials, they occur under very different conditions:

Home Compostability: Home composting happens in much lower-temperature environments, typically ranging from 50°C to 60°C (122°F to 140°F). Materials that are home compostable break down in these conditions without the need for professional or industrial equipment. They must be capable of decomposing naturally and safely in the average backyard compost bin or pile, or in nature.

Industrial Compostability: In contrast, industrial composting is a controlled process that operates at much higher temperatures (typically around 60°C to 70°C / 140°F to 158°F) to speed up the breakdown of organic materials. Industrial composting facilities have the machinery and processes to handle large volumes of waste and ensure materials degrade efficiently. Again we are in the technical cycle, with its downsides.

Looking ahead

The future of packaging must be circular and regenerative. As businesses it is our responsibility to provide solutions that fulfill these criteria and to spearhead such solutions in the industry. The more join the movement, the more we can turnaround towards a regenerative model of consumption. CAMM is part of that movement, not in the niche, but at scale.

DO WE CONSIDER CAMM A PLASTIC?

From 'Plastic' Eggs to Innovative Materials: Navigating the Complexities of Environmental Legislation and the Pursuit of Sustainability

From 'Plastic' Eggs to Innovative Materials: Navigating the Complexities of Environmental Legislation and the Pursuit of Sustainability

The European Union's Single-Use Plastic Directive (SUPD) represents a landmark effort in the fight against plastic pollution, marking a pivotal shift towards a future less burdened by plastic waste. Lauded for its ambitious goals, the SUPD testifies to the EU's commitment to environmental sustainability. The challenge however: the SUPD's broad definition of plastic encompasses sustainable materials that have nothing to do with plastic waste and on the contrary – when faced with a barrier – lose out on the opportunity to create positive environmental impact.

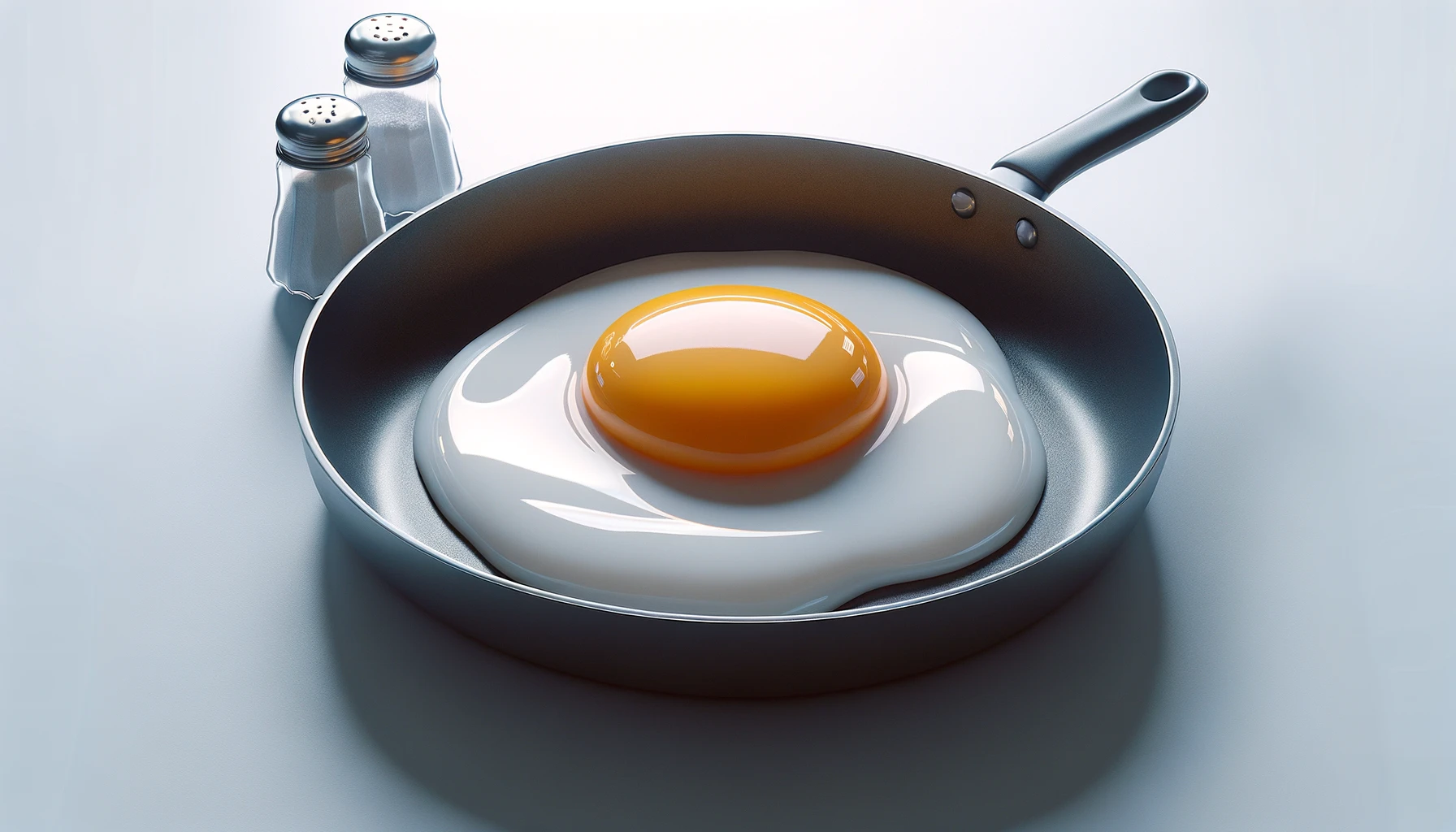

EGG + SALT + INGREDIENTS + HEAT = PLASTIC

To show the absurdity of the situation: The SUPD's definition of plastic is so broad that it could potentially cover everyday items like a fried egg or the vanilla extract in your ice cream. This peculiar scenario arises from the directive's classification of 'plastic' as any material consisting of a polymer which may be synthetically altered, for example, by heat, and which acts as a main structural component of final products. By this measure, the protein-based polymer in an egg, when salted, mixed with ingredients, and heated, could fall under the umbrella of 'plastic', despite the fact that it leaves no trace of microplastics in its wake.

This conundrum presents itself not just as a matter of regulatory semantics but as a significant challenge in our collective quest to combat global plastic pollution. It brings forth a crucial question: Where do we draw the line? When does an item cease to be a harmless part of our daily lives and become a contributor to the ever-growing plastic problem?

WE NEED TO CONSIDER THE ENVIRONMENTAL IMPACT OF MATERIALS

The issue at hand is emblematic of a larger narrative in environmental regulation - the delicate balance between the necessity of stringent measures and the practicalities of their implementation. Regulation is important to create an equal level playing field in favor of more sustainable business practices. However, it is equally important to approach these regulations with a lens of practicality and impact. Surely, common sense tells us that a fried egg does not belong under the SUPD. So what can a framework be to balance unnecessary barriers? We believe – the perspective of the actual impact of materials, not if they should be considered as plastic or not. Materials that are hazardous to the environment need to be banned, materials that are not, should be supported.

AND THIS IS WHY CAMM IS NOT A PLASTIC

While CAMM mirrors plastic in look and function and is a polymer, it sets a new standard for environmental care as it

Is toxin and microplastic-free

Leaves no harmful residues when leaving the product or recycling cycle

Is home compostable (faster than wood in the forest)

And an enabler for recycling

Moreover, CAMM is working on becoming a carbon storage solution starting 2025, e.g., made from wheat or sugar cane residue streams. It already includes minerals and cellulose-based ingredients making CAMM a material close to nature. Fully built-out CAMM will be holistically sustainable from raw material to end-of-life.

IT’S ABOUT FINDING THE RIGHT BALANCE

Regulations, while crucial, can only offer a framework and must be crafted carefully to avoid unintended consequences. It's clear that businesses, with their agility and innovative capacity, can often move more swiftly than regulatory bodies, utilizing their flexibility.

However, the necessity for regulation stems from the current lack of fair play in environmental protection. Regulations are still essential to level the playing field, ensuring that all stakeholders adhere to sustainable practices. They are not just a constraint but a guide, helping to steer the collective efforts towards a more sustainable future.

Achieving true sustainability requires a delicate balance. Effective regulation must support and encourage innovation without stifling it, fostering an environment where sustainable solutions can thrive and make a meaningful impact.

IT ALL STARTED WITH A BOLD QUESTION

It all started with a bold question: what if we could solve the global (micro)plastics challenge?

What if we could solve the global (micro)plastics challenge?

In a world grappling with environmental crises, the urgency of sustainability has never been more apparent. Climate change, biodiversity loss, and the pervasive harm caused by conventional plastics underscore the need for change. This is the backdrop against which we started our journey as CAMM in 2019 to design a global solution to tackle (micro)plastic and packaging waste.

TRUE SUSTAINABILITY - A HOLISTIC VISION

From the start, we wanted to do things right. As experts and longstanding sustainability practitioners, we stand for impact and scale. We are careful not to create another “green” solution with lofty words but little substance. Sustainability, for us, goes beyond checkboxes and standard practices. It's about recognizing the intricate interdependencies between environmental concerns, human rights, health, and business conduct. Our approach considers the complexity of sustainability, delving into climate change, biodiversity preservation, natural habitat protection, responsible raw material use, efficient production, labor rights, workers' welfare, and social and climate justice along our supply chain. In a nutshell, we strive to conduct business holistically and strike equitable balances that benefit both people and the planet, all with a global perspective.

INNOVATION AS OUR CATALYST

If it were that easy, many before us would have already come up with great solutions. But real solutions require thinking outside the box, not only in terms of science but also in terms of ensuring such a solution can persist in the market where sustainable and conventional business models still compete. This is why we strongly emphasize innovative thinking in our work. “This is not possible” is a no-go in our company culture.

Our science innovation:

One of our groundbreaking innovations is the way we've been able to blend PVOH (polyvinyl alcohol) into our CAMM material. PVOH is a great building block because it is biodegradable, water-soluble, and non-toxic. It’s been around for decades, but nobody was able to harness its great sustainability qualities. By stacking together different material technologies and processing technologies we managed to harness the full potential of PVOH. Blending it with eco-conscious fibers and materials was key and created material applications that are stable, affordable, and holistically sustainable. The one last piece to work on - transitioning the PVOH part of CAMM - that until today is only available fossil-based - is another of the innovations we are focusing on.

Our carbon innovation:

PVOH only exists fossil-based today, though the carbon is bound back into the soil or water if in contact with humidity. Nevertheless, our vision is for CAMM to become a carbon storage. Together with partners, we are building the first green PVOH supply chains out of agricultural waste (of course with no food competition or deforestation involved). This will transform the last non-biobased piece of CAMM and make CAMM a carbon storage starting in 2025.

Our business model innovation:

Realizing the material works and is as sustainable as can be imagined, we have been building together an ecosystem of partners that are enabling CAMM to scale production, processing, and distribution, recognizing that the greatest sustainable solutions do not succeed if there is no consciously designed enabling environment around them.

In fact, while we love disruption, we believe that impact is more important. We know we need big players on board for maximum scale. Therefore, we don’t aim to replace traditional businesses; we want to enrich them with our solution, supporting their respective transformations towards sustainability. This will bring CAMM onto a much broader platform than we could achieve by ourselves.

THE RIGHT COLLABORATIONS TO LEVERAGE CAMM

We welcome customers and partners who share the mindset of a joint responsibility towards tackling the (micro)plastic challenge. This means being willing to co-invest in the ramp-up phase and participate in jointly tackling the challenges we may encounter in the building phase. Speed, impact, and an entrepreneurial way of working together are important for us. But most of all, we are seeking out those who want to make the solution available for all. Focus on scale, not on exclusivity.

LOOKING FORWARD

We are continuously upgrading the company, so CAMM is the best possible version of itself. The CAMM solution is larger than just us, and we can’t wait for it to scale to the maximum impact possible.

In fact, we made a bold calculation recently. We were curious what we could achieve if we were able to replicate the CAMM production everywhere. This is not a matter of technology but “only” access to finance and the right partners.

What we found out was astounding: The CAMM technology could replace 50% of global plastic waste!